What is the tolerance standard for precision injection molds?

Precision injection mold molding tolerance is a key indicator in the mold manufacturing, strictly follow the tolerance standard can ensure that the mold's high precision and high stability. So, what is the precision injection mold molding tolerance standard? First, the concept of molding tolerance molding tolerance refers to the mold components [...].

- Info

Precision injection mold molding tolerance is a key indicator in the mold manufacturing, strictly follow the tolerance standard can ensure that the mold's high precision and high stability. So, what is the tolerance standard for precision injection molds?

I. The concept of molding tolerance

Molding tolerance refers to the range of dimensional deviation allowed in the manufacturing and assembly process of each component of the mold. For precision injection molds, the control of molding tolerance is particularly important, because any small dimensional deviation may lead to product size, surface defects or functional failure.

Second, the precision injection mold mold tolerance standards

1. Dimensional accuracy classes

According to the national standard GB/T 1804-2000 Tolerances and Fits, dimensional tolerances can be categorized into four grades: Precision Grade (IT5-IT7), High Accuracy Grade (IT8-IT11), Medium Accuracy Grade (IT12-IT14) and Rough Grade (IT15-IT18). For precision injection molds, an accuracy class of IT6 or higher is usually required.

2. Cavity and core fit tolerances

- Parallelism and perpendicularity toleranceThe general requirement is within 0.01mm to ensure the precise fit of the cavity and core and to avoid defects such as partial wall and flying edge of the product.

- Clearance fit tolerances: For slider, guide pillar, guide sleeve and other moving parts, the fit gap is usually controlled between 0.005mm ~ 0.02mm, both to ensure smooth movement, but also to prevent loosening and wear.

3. Machined surface roughness

- Cavity surface roughnessIn order to obtain good product surface quality, the cavity surface roughness is generally required to reach Ra 0.2μm or less.

- parting surface: The roughness of the parting surface should be within Ra 0.8μm to ensure good mold closure and prevent material leakage.

4. Tolerance accumulation control

In the process of mold design and manufacturing, it is necessary to consider the cumulative effect of tolerance, and take the method of optimized design and precision machining to control the cumulative tolerance within the permissible range.

III. Factors affecting molding tolerances

1. Material stability

The coefficient of thermal expansion, hardness and wear resistance of the mold material will affect the dimensional stability. Selection of high quality mold steel, such as S136, H13, etc., can reduce processing deformation and dimensional deviation.

2. Processing equipment and techniques

- Precision of processing equipment: High-precision CNC machine tools, grinding machines, and electrical discharge machining equipment are the basis for ensuring machining accuracy.

- Process parameters: Reasonable selection of cutting volume, feed rate, coolant and other parameters to prevent machining stress and thermal deformation.

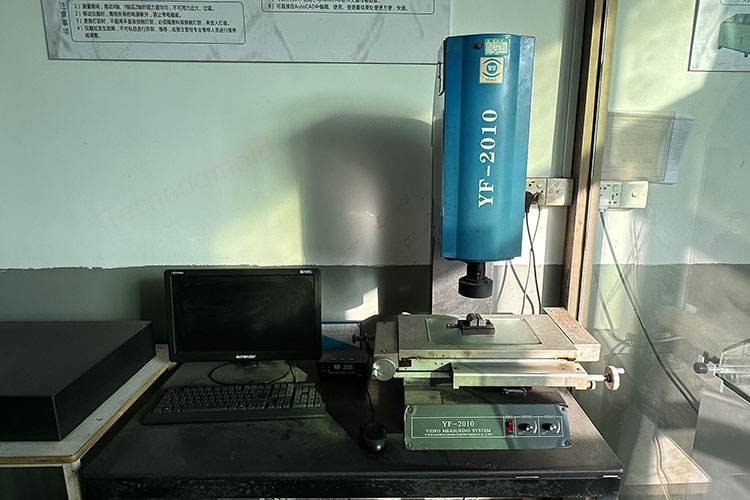

3. Measurement and inspection instruments

Use high-precision measuring equipment, such as CMM, projector, etc., for real-time inspection of machining dimensions, timely detection and correction of deviations.

Fourth, how to ensure that the molding tolerance in line with the standard

1. Rigorous design standards

In the mold design stage, develop detailed dimensional tolerance tables and technical requirements, and clearly mark the key dimensions and mating parts.

2. Precision machining and assembly

- Process control: Adopt precision machining process, such as precision grinding, mirror polishing, etc., to reduce machining errors.

- Assembly process control: Use high-precision positioning and clamping devices during assembly to prevent assembly errors.

3. Comprehensive quality management

Establish a perfect quality management system, comprehensive management of design, procurement, processing, assembly, inspection and other links to ensure that each link meets the tolerance requirements.

Techeng Technology is a professional precision mold manufacturer, focusing on precision connector molds, high temperature plastic mold injection molding such as PEEK, LCP, PBT, PEI, PPS, PPSU, PA66, etc. open mold injection molding production. Welcome to contact us.